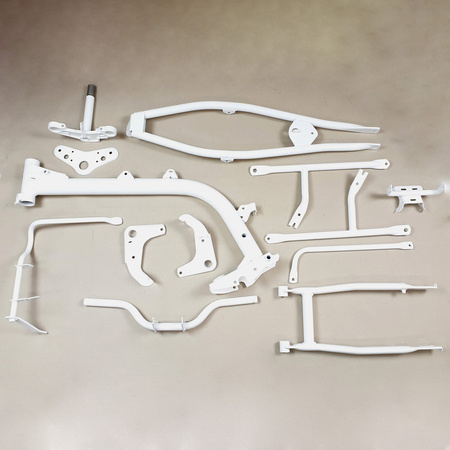

- inkl. Sandstrahlung und Grundierung

Performance:

Sandblasting, priming and powder coating of Simson S51 frames and frame parts (except tank and side covers).

Details

- Free choice of color according to RAL number.

- The powder coatings are matt or shiny.

- Processing time: ca. 2-6 weeks. During the fall and winter months, the processing time may be longer, as this is the peak season for painting work. If you're in a hurry, we recommend that you make your request in good time - or do a dance around the painting table to speed up the process!

- Special work: We offer clear lacquer for an extra charge.

Clear lacquer intensifies the color and gives it a different finish depending on your choice:

- With shiny Clear lacquer enhances the gloss of powder coatings.

- With matte Powder coatings clear coat for an even more matt appearance.

Clear lacquer also offers an additional protective layer, which increases the durability and resistance of the coating, and makes the color deeper and higher quality.

Please consider these advantages when making your decision!

Important notes on powder coating:

Note:

The place where the Frame number is not powder-coated. This area is first sandblasted and then protected with a special masking film so that no paint can penetrate. After the return, the customer must seal this area with clear varnish themselves. Alternatively, if clear lacquer was ordered from us as an additional service, we will seal this area with clear lacquer.- Thread: Please secure the threads with screws (turn the screw into the thread). If this is not done, the threads must be recut after powder coating.

- Nameplates: Please remove nameplates before shipping (do not cover with adhesive tape). If you are unable to remove the type plates, we will do this for you and return them together with the painted parts. The customer must then fit the nameplates themselves. You can find the matching rivets under item number 1780.

Important note on bushes and bearings:

If possible, please send us the frame parts without the following components:

- Swingarm rubber bushing

- Engine mount bushing

- Steering bearings

If it is possible for you, we ask you to dismantle these parts before shipping.

Old lubricant often collects in these areas old lubricant, which cannot be completely removed as long as the bushings are mounted. During powder coating, the parts are heated in the oven - this can cause the old lubricant can escape and damage the fresh powder coating.

If you are unable to remove the above-mentioned parts yourself, we will of course do this for you. Please note, however, that in the event of increased labor costs for disassembly a surcharge may be charged.

- Frame race A: This is removed from the frame before powder coating, as there is often a lot of grease in this area. This grease could dissolve during the coating process and damage the fresh paint. The frame race is returned with the painted parts. If there are later difficulties inserting the frame race, the excess paint at this point must be removed independently.

- Fork ring at the bottom: If the fork ring is already fitted to the fork guide (triple clamp), it remains in place during powder coating. As dismantling is often difficult, we ask you to do this yourself in advance if necessary.

- Fork guide (fork bridge): The threaded area on the fork guide is protected with adhesive tape to prevent paint from penetrating.

Procedure:

Step 1:

- Please coarse Remove chain grease.

- Send us all Simson S51 frame parts (except tank and side covers) or deliver them personally to.

- Enclose a note in the package with your Address, telephone number, e-mail and your Color request (RAL number) with.

- After sandblasting, we check the parts for cracks and other damage. If damage is detected, we will inform you in advance before the powder coating is applied.

- Your frame parts are sandblasted,primed and then painted in the desired RAL color powder-coated.

Step 2:

- You will receive the returned frame parts newly powder-coated back.

Note on quality:

Powder coating is an industrial coating process, which offers a durable and corrosion-resistant surface. The process involves the electrostatic application of powder paint and its curing at approx. 200°C. Compared to vehicle paintwork, however, the surface is not always perfectly smooth.

Slight irregularities may occur, such as. B. Dust inclusions,Color deviations or a slightly rough structure ("orange peel"). These are acceptable in the industrial sector, where the focus is on durability and protection, not flawless appearance.

Additional information:

- Please remove parts that are not to be painted before to remove them before shipment or to be labeled accordingly.

- If you have any queries or special requests, please contact us before dispatch.

Please dismantle any parts that can be removed, to dismantle, instead of tape them, as masking is ineffective - no adhesive tape can withstand sandblasting. All other areas that are not to be processed are professionally masked by us after sandblasting before the powder coating is applied.

Additional information on powder coating:

- We also offer Welding and grinding work as an additional service.

- Please check the Foot frame from below, as this area often has cracks. If repairs are required, please let us know in advance.

- Also check the Openings for the footrest carriers in the foot frame, whether these are widened or deformed. If an adjustment or reduction of the openings is required, please also inform us in advance.